Floor heating with foam dry floor heating module Under Floor Heating XPS Boards

Payment Terms: TT or LC

Ref Price : 1-20 USD/METERS

Sino-Sources Service Pledge

-

Quality Product

Quality Product

-

Credit Purchasing

Credit Purchasing

-

Credit Rating

Credit Rating

-

Timely Delivery

Timely Delivery

-

Order On-line Tracking

Order On-line Tracking

-

Credit Services

Credit Services

Qulck Details

-

Place of Origin:Tianjin China (Mainland)

-

Brand Name:wmdtrade

-

Model Number:Xps extruded board

-

Product name:Extruded polystyrene insulation board

-

Color:Blue pink white

-

Material:Polystyrene resin

-

Density:≥28 kg/ m3

-

Thermal Conductivity:≤0.03 W /m .k

-

Compressive strength:≥150 pa

-

Aging time:Natural conditions ≥42d

-

Water absorption rate:≤1.5 %

-

Size:Can be customized to any size

-

Port:Tianjin xingang

The dry floor heating module introduction:

The dry floor heating module also name floor heating board is a thin dry floor heating installation system material ,it is an insulation layer and keep the warm water pipe heat up, wherein the insulation layer is laid on the foundation, and the insulation layer is provided with a groove for placing a warm water pipe, and the warm water pipe is placed in the In the groove, a heat insulating groove is disposed between the grooves.

advantage:

1. Dry floor heating The heat-insulating cavity formed between the heat-conducting layer and the heat-insulating groove blocks the heat from being transmitted downward, preventing heat loss, reducing heat loss by more than 60%, and increasing the temperature of the return water. The water supply temperature difference is small.

2, relatively traditional floor heating, energy saving 25-30%, in the case of hot water 45 ° C, the normal room can maintain about 22 °C.

3. Solve the problem of concrete weight in traditional technology. The traditional method weighs 25 kilograms per square meter, and the dry process weighs less than 1 kilogram per square meter.

4. Solving the problem that the structure in the traditional process increases the thickness too much. The traditional method is increased by 8-10 cm, and the dry process is increased by 2-3 cm.

5. The dry process presses the warm water pipe in the groove of the heat insulation layer, thereby effectively protecting the warm water pipe, so that the warm water pipe is hardly subjected to external pressure, effectively increasing the life of the water pipe.

Heating module product parameter:

Heating module product Specification:

| Product model number | WT4501 |

| Product dimensions | 450*450*25mm |

| Product weight | 2.5kg/ meter square |

| Manufacturing materials | extruded polystyrene/xps |

| Coiler separation | 15 cm |

| Number of products per box | 25Pipe diameter |

| Main purpose | Used for heating system installment (both wet-type and dry –type) |

| Water vessel module | 400*400*25mm |

| Output | 200 meter square/day |

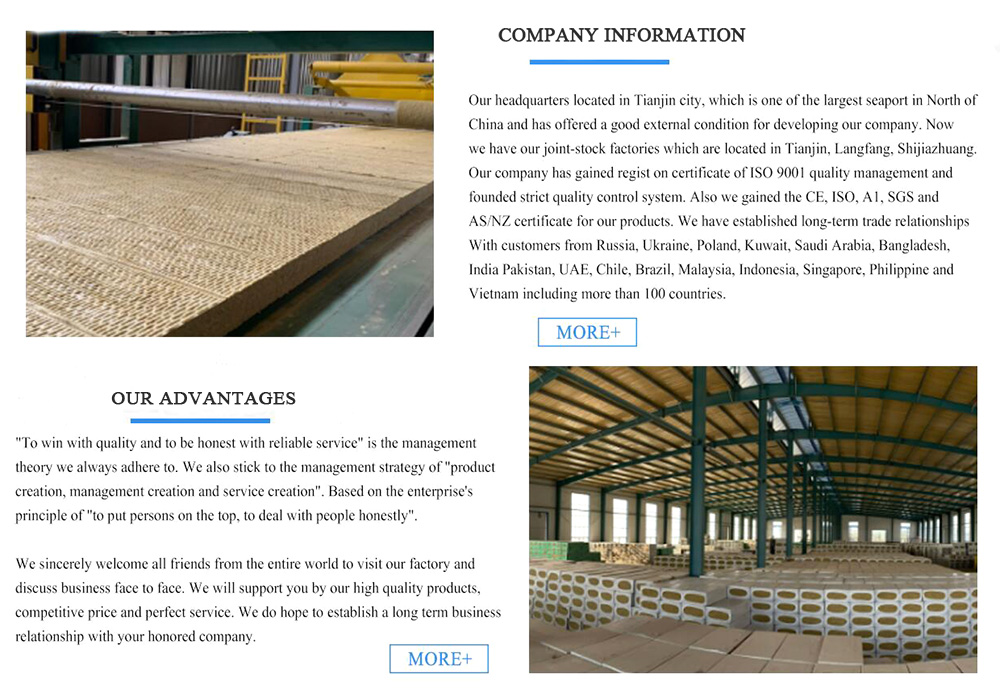

WanMaiDe estabished in 2001, a leading manufacturer and exporter of Glass Wool, Rock Wool, Rubber Foam, Foam Glass,Extrude Polystyrene/XPS, Phenolic foam board insulation in China. After more than 20 years' development, we totally have 10 producing lines for glass wool insulation,5 producing lines for rock wool insulation and more than 30 producing lines for rubber foam insulation.

We had mad OEM production for WANMAIDE which are popular due to the high quality and competitive price all over the world.

Collection

Collection